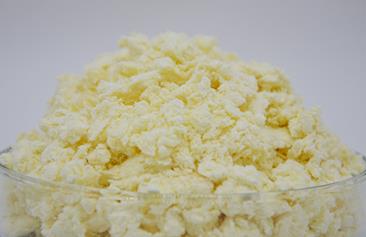

VICWA® Pulp

Para-aramid pulp is made from Vicwa filament yarn whose composition is poly(para-phenylene terephthalamide). After a series process of cutting, grinding and suspending in water, the fiber is fibrillated into pulp. The pulp not only inherits the high-strength, high-modulus, high-temperature resistance, abrasion resistance and excellent chemical stability from para-aramid fiber, but also has high dispersibility, specific surface area and grip force to provide reinforcement and viscosity control under shear stress.

Para-aramid pulp is widely used in high-performance friction and sealing field, increasing its effect and service life significantly.

Average Length: 0.6 -1.4mm

Specific Surface Area : 7-15m /g

Specification

| Specification | C.S.F. | Specific Surface Area | Moisture Content | Average Length | Thermal Decomposition Temperature | Packing |

| [ml] | [m2/g] | [%] | [mm] | [℃] | kg/bag | |

| VP 230 | 320-420 | 7-10 | 7 | 0.6-0.8 | 550 | 5 |

| VP 240 | 420-500 | 9-15 | 7 | 0.6-1.0 | 550 | 5 |

| VP 250 | 500-800 | 9-14 | 7 | 0.8-1.2 | 550 | 5 |

| VP 260 | 600-880 | 8-13 | 7 | 1.0-1.4 | 550 | 5 |

APPLICATION

Aramid Paper Aramid Paper |  Aramid Honeycomb Aramid Honeycomb |  Run Flat Tyre Run Flat Tyre |  Friction Materials Friction Materials |